Inventory Holding Cost and Tariff Analysis Tool

Real-time Estimate:

Safety Stock: 0.00 units

Holding Cost: $0.00

Formula Explanation

- D (Average Daily Demand): Average number of units sold daily. If your store sells 75 units daily on average, input 75.

- L (Average Lead Time in Days): Number of days between placing an order and receiving goods. For example, a supplier who delivers in 7 days means L = 7.

- σD (Demand Standard Deviation): Measures variability in daily demand. High variation = more uncertainty = higher safety stock.

- σL (Lead Time Standard Deviation): Indicates how consistent your supplier is. More variance = greater need for buffer stock.

- Z (Z-score): The service level you want to achieve. Higher Z = fewer stockouts, but higher inventory cost.

- 1.28 for 90% service level

- 1.65 for 95% service level

- 2.05 for 98% service level

- 2.33 for 99% service level

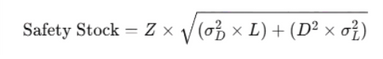

Formula:

Safety Stock = Z × sqrt((σD2 × L) + (D2 × σL2))

This ensures enough stock to meet demand despite supply or demand fluctuations.